Detailed Case Study: Full-Automatic Rice Milling Line Project with a Malawian Customer

Background and Needs Analysis

In the global rice industry, enhancing processing efficiency and product quality is a major concern for many companies. As a primarily agricultural country, rice is a significant crop in Malawi. However, traditional processing methods cannot meet modern market demands for high-quality rice. Therefore, the Malawian customer sought to improve rice processing efficiency and the quality of finished products by introducing an advanced full-automatic rice milling line, aiming to increase their market competitiveness.

When choosing a supplier, the customer conducted a thorough evaluation of the machines' stability, efficiency, product quality, and after-sales service. After multiple comparisons and assessments, they chose our company due to our extensive experience and excellent reputation in the rice milling machine industry.

Equipment Solution and Configuration

We provided the customer with a complete 30-ton full-automatic rice milling line, including the following equipment:

Cleaning and Destoning Machine: Used to remove stones, mud, and other impurities from the paddy, ensuring the purity of the rice for subsequent processing. Its high cleaning efficiency lays a solid foundation for the following stages.

Husk Separator: Utilizes high-speed impact to remove the outer husk of the paddy, improving the quality of the finished rice. The design ensures that the rice grains are not damaged during husking.

Paddy Separator: An effective device for separating brown rice from paddy, ensuring only brown rice proceeds to the next processing stage, thereby reducing unnecessary energy consumption.

Emery Roller Rice Mill: This machine uses emery rollers to initially process the brown rice by removing the bran layer, ensuring the grains maintain their shape while minimizing breakage.

Iron Roller Rice Mill: Further refines the rice grains, making their surface smoother. Advanced technology is used in this machine to enhance the smoothness of the grains and reduce broken rice.

Water Mist Polisher: In the polishing process, this machine sprays a fine mist of water and uses polishing rollers to make the surface of the rice grains shinier, enhancing the product's appearance and quality.

Color Sorter: Utilizes advanced optical recognition technology to identify and remove discolored grains and impurities, ensuring the consistency and quality of the finished rice.

Rice Grading Sieve: Classifies rice grains according to size, ensuring uniformity in the finished product, which is particularly important for high-end markets where consumers demand consistent product appearance.

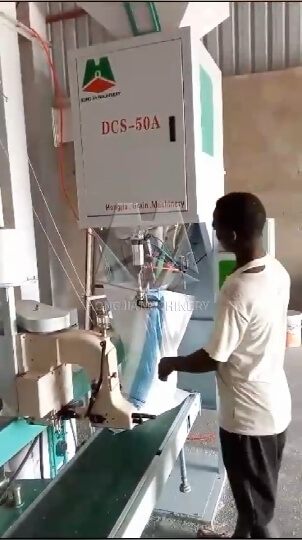

Packing Machine: Automatically packs the finished rice according to preset specifications, ensuring fast and accurate packaging, and reducing human error.

Dryer: Mainly used for drying paddy or brown rice to ensure stability during storage and transportation. The dryer is designed to ensure even drying, maintaining an appropriate moisture content in the grains.

Installation and Commissioning

From equipment transportation to installation and commissioning, we provided comprehensive support throughout the project. We strictly adhered to international shipping standards during transportation to ensure the safe and intact arrival of the equipment. Upon arrival, we dispatched a team of experienced engineers to the site for installation and commissioning.

During installation, the customer encountered a minor issue: a critical component of the dryer was damaged. To avoid delaying the overall project schedule, we acted promptly, air-freighting a new component to the customer. Simultaneously, our engineering team provided on-site guidance and remote support, helping the customer resolve various technical issues encountered during installation, and ensuring the equipment was put into operation smoothly.

After-Sales Service and Long-Term Cooperation

Even after the project's completion, we continued to support the customer. Our after-sales team regularly contacts the customer to check on the equipment's operation and provide necessary technical assistance. The customer has expressed high satisfaction with our timely service response and high-quality technical support.

The customer reported that they were very pleased with the performance and output of the equipment, particularly impressed with the quality of the rice grains and the packaging results. They mentioned that the stable operation of the equipment significantly improved their production efficiency and reduced labor costs. Furthermore, the customer highly praised our after-sales service, which has made them confident about future collaborations.

Based on this pleasant cooperation, the customer not only expressed their willingness to continue purchasing our equipment and spare parts but also mentioned that they would recommend our products to other friends and colleagues in need of similar equipment. We also look forward to maintaining a long-term partnership with this Malawian customer and jointly advancing the local rice industry.

Conclusion

This successful cooperation with the Malawian customer has demonstrated our leading technology and excellent service capabilities in the rice milling machinery field. This project not only affirms the quality and technical level of our products but also recognizes our team's collaboration and customer service. We will continue to be customer-oriented, constantly innovate and improve, and provide better rice milling machinery solutions to customers worldwide.

Hongjia Grain Machinery Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing plants, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

If You Are Ready to Start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Hongjia Grain Machinery Co., Ltd

Email: info@ricemillplants.com

Phone/Whatsapp: 0086 13196770111

Comments

Post a Comment