30T/D Rice Milling Production Line Successfully Installed and Trial Run Completed in Uzbekistan, Supporting the Client’s High-Quality Rice Processing

Recently, our company successfully delivered a complete 30T/D rice milling production line to a client in Uzbekistan. The equipment has been successfully installed and undergone trial runs, marking a significant step forward for our company in the Central Asian market. This project also provides robust technical support for the client to achieve efficient, intelligent, and modernized rice processing.

Client Background and High-Quality Standards

The client for this project is a well-established large-scale grain processing company in Uzbekistan, renowned for producing high-quality rice products. With the increasing demand in the market, the client sought to upgrade its equipment to improve production efficiency while ensuring that the quality of the processed rice meets international standards. Therefore, the client had stringent requirements for the performance of the rice processing equipment, particularly in terms of rice yield, product appearance, and quality.

To meet these high standards, the client partnered with us to purchase a customized 30T/D rice milling machine for their large-scale rice processing plant expansion. This production line not only needed to meet the client's high output demands but also ensure that the quality of the finished rice was exceptional, with low breakage rates and high rice yield, meeting market expectations for premium rice products.

Customized Equipment Design Solution

To fulfill the client's strict requirements, our technical team conducted multiple rounds of in-depth communication with the client to fully understand their factory layout, production process, and specific product needs. Based on this, our design team created a customized, efficient, and intelligent rice milling production line solution that integrates advanced equipment and technologies, covering all the major stages of rice processing.

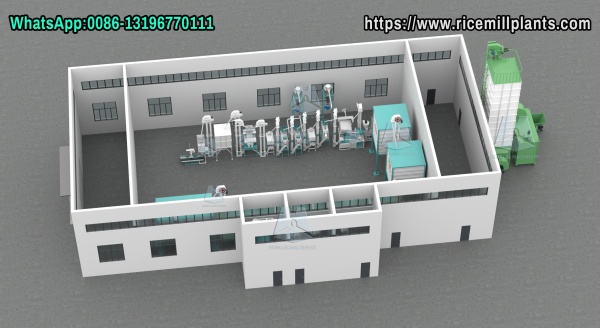

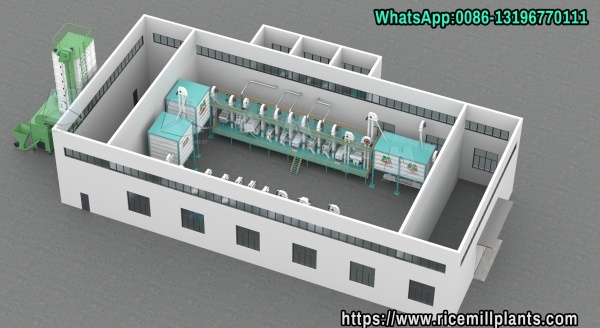

We have a strong rice milling machine design team. Before you purchase the machines, our designers will tailor the equipment's design and layout based on your specific needs and site conditions. Prior to installation, you will have a clear understanding of how your facility will look once the equipment is set up, allowing you to plan the layout of your plant in advance. This ensures a smooth installation process and lays a solid foundation for the efficient operation of your production line.

Key Equipment and Production Processes of the Line:

Vibrating Cleaning Sieve: This equipment is used to clean large impurities such as stones and straw from the raw paddy. The vibrating sieve effectively separates impurities, ensuring smooth operation in subsequent processes and protecting the equipment from damage by foreign objects.

De-Stoner: Utilizing the principle of weight differences, this machine effectively removes small stones and heavy impurities from the paddy, ensuring purity during the processing stages and improving the quality of the finished rice.

Paddy Husker: With an advanced pressure control system, this machine efficiently separates the husk from the rice grains. By precisely adjusting the husking pressure, it achieves a husking rate of over 95%, while reducing grain breakage and preserving the integrity of the rice.

Paddy Separator: This machine separates brown rice from unhusked paddy. Using airflow and screening techniques, it ensures that only brown rice moves forward to the next stage, while the unhulled paddy is returned for re-husking.

Rice Whitener: The core equipment of the production line, uses multi-stage whitening technology to control the degree of whitening during processing. It ensures a high rice yield while guaranteeing a uniform color and smooth surface of the finished rice grains. The machine’s adjustable settings accommodate different paddy varieties, maximizing rice yield.

Color Sorter: Using high-precision optical detection technology, the color sorter automatically detects and removes discolored, spotted, or impurity-laden rice grains, ensuring uniform color in the finished product and enhancing its market competitiveness.

Rice Polisher: After the whitening process, the rice is polished to remove bran powder, leaving the grains smooth and white. The polisher significantly enhances the visual appeal and market value of the finished rice.

Rice Grading Sieve: This machine grades the rice based on grain size and quality, ensuring that the product meets the specific market demands. The grading sieve accurately classifies rice into premium, first-class, and standard grades, catering to the client’s diverse market positioning.

Length Grader: This further sorts the finished rice based on grain length, ensuring consistency and standardization in the final product, suitable for the high-end market.

Electronic Packaging Scale: Paired with an automatic packaging system, this equipment accurately weighs and packs the rice, ensuring efficiency and precision in the packaging process while minimizing manual labor.

Elevators: Multiple elevators are used throughout the production line to transport materials efficiently between processing stages, enhancing production continuity and avoiding delays caused by manual handling.

Efficient Production and Rigorous Installation & Commissioning

Once the production process design was confirmed with the client, our company promptly arranged for the equipment to be manufactured. Given the complexity of the machinery and the scale of the project, we paid close attention to every detail during production, ensuring that the equipment met the required standards and fulfilled the client's expectations.

After the equipment was manufactured, it was packaged and shipped to the client’s factory in Uzbekistan. Although we were unable to send on-site installation engineers due to geographical constraints, our engineers provided remote video guidance. With their support, the client’s team successfully completed the installation and commissioning. During the trial run, the production line operated smoothly, with all equipment performing as expected or even exceeding the client’s expectations, particularly in terms of rice yield, grain integrity, and uniform color. The client was extremely satisfied with the equipment’s overall performance and praised our company’s technical support.

Client Feedback and Future Cooperation

Following the successful trial run, the client expressed high satisfaction with the efficiency, intelligence, and energy-saving features of the equipment. They highlighted that the equipment’s high rice yield, low breakage rate, and superior rice quality fully met their expectations for the premium rice market. In particular, the combination of the rice whitener and the color sorter not only improved product quality but also significantly enhanced production efficiency, enabling the client to better compete in the market.

After the successful project implementation, the client expressed their intention to deepen cooperation with our company. They plan to expand the production line in the future and purchase more grain processing equipment to support their business expansion in Central Asia and globally. Both parties see great potential for future collaboration, and we are excited to continue providing high-quality, customized grain processing equipment to help the client achieve greater success in the global market.

Our Company’s Future Outlook

The successful completion of this project has not only strengthened our brand presence in Uzbekistan and the wider Central Asian market but has also laid a solid foundation for our global expansion in the grain processing equipment sector. We will continue to uphold the principle of "customer first, quality foremost," driving technological innovation, optimizing product performance, and providing more intelligent, eco-friendly, and efficient grain processing solutions.

Looking ahead, we are committed to expanding our presence in international markets, increasing our global market share, and helping more clients establish modern, intelligent grain processing lines, contributing to the sustainable development of the global grain processing industry.

Hongjia Grain Machinery Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing plants, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

If You Are Ready to Start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Comments

Post a Comment