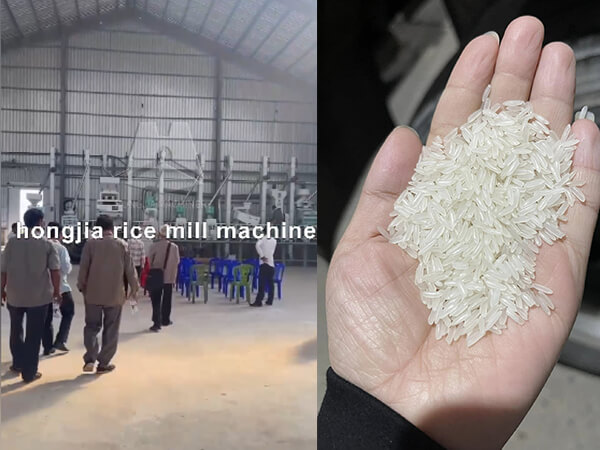

Success Story: Cambodian Client Purchases Fully Automatic Rice Milling Equipment

Client Background and Requirements

A rice processing company in Cambodia, known for its commitment to producing high-quality rice, was facing increasing market demand. The client sought to upgrade their production line with advanced rice milling equipment to enhance efficiency and product quality, aiming to stand out in the local market. They required equipment that could thoroughly clean raw materials, remove impurities, and finely grade and sort rice to ensure the purity and appearance of the final product. To achieve these goals, the company decided to purchase a complete set of advanced fully automatic rice milling equipment.

Equipment Selection

The client chose our company from among many suppliers due to our strong reputation and extensive experience in the industry. After detailed discussions and needs analysis, we recommended the following complete set of equipment and provided a tailored solution:

Cleaning and De-stoning Machine:

Utilizes vibration screening and airflow separation to effectively remove stones, metal fragments, and other impurities from the paddy, ensuring the cleanliness of raw materials.

The machine's efficiency and reliability received high praise from the client.

Rice Husker:

Precisely controls the husking process to remove the husk from the paddy while protecting the integrity of the rice grains, minimizing broken rice.

The unique design and superior performance of this machine are well-regarded in the market.

Paddy Separator:

Uses a multi-layer screening structure to effectively separate husk from brown rice, ensuring minimal grain loss.

Rice Whitener:

Gradually remove the bran layer from rice grains through multiple stages, preserving the nutritional value and natural flavor of the rice.

The specially designed whitening chamber minimizes heat generation, preventing the rice grains from overheating and affecting quality.

Water Mist Polisher:

Employs water mist polishing technology to smoothen and whiten the surface of the rice, effectively removing dust and impurities, and enhancing the rice's appearance and marketability.

Rice Grader:

An efficient grading system that classifies rice into various grades based on size and quality, ensuring uniformity and consistency in the final product.

Rice Color Sorter:

Uses high-precision optical detection technology to automatically identify and remove rice grains with color variations, spots, and other defects.

The machine's high sensitivity and accuracy ensure stable and high-quality rice products.

Fully Automatic Rice Packaging Scale:

An efficient packaging and weighing system that not only increases production efficiency but also ensures precise weight accuracy for each package of rice.

The automated packaging process reduces manual errors and labor costs.

Installation and Commissioning

After the equipment arrived, we dispatched an experienced technical team to handle on-site installation and commissioning. The team meticulously checked every detail of the installation to ensure seamless integration of all components. During the commissioning process, our engineers also provided comprehensive training for the client's operators, helping them master the use and maintenance of the equipment. The entire commissioning process went smoothly, and all equipment reached optimal operating conditions.

Client Feedback and Results

After the equipment was put into operation, the client expressed high satisfaction with the quality of our products and the rice produced. The new equipment not only increased production efficiency but also significantly improved rice quality. In particular, the equipment's performance in removing impurities, enhancing grain luster, and reducing broken rice exceeded the client's expectations. The rice produced has been well-received in the market, with sales significantly increasing, positioning the client company as a leading rice producer in the local industry.

The client also highlighted the ease of operation and maintenance of our equipment, which greatly reduced human errors and downtime during production. This reliability and user-friendliness have made their production process more efficient.

Looking ahead, the client expressed interest in continuing to purchase our equipment and recommending our products and services to other industry peers. This collaboration not only helped the client enhance their production capacity but also reinforced our brand image in the Cambodian market.

Conclusion

This successful collaboration reaffirms the excellent quality and performance of our rice milling equipment. We will continue to uphold the principles of "good quality, good service," providing superior products and comprehensive services to customers worldwide, helping them achieve greater success in the competitive market.

Comments

Post a Comment