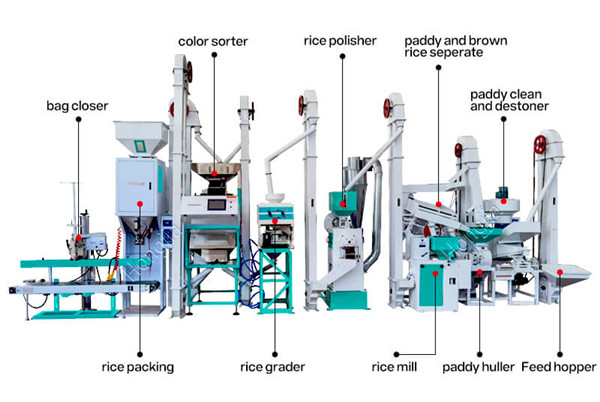

Recently, we had the pleasure of hosting a customer from Kenya. After comparing multiple suppliers online, this customer ultimately purchased a complete set of 15-ton rice milling machine equipment from us. This investment is crucial for their rice milling business in Kenya. The complete set of rice milling machine equipment constitutes a comprehensive production line, covering every step from paddy to the final polished rice. It includes machines for rice de-stoning, rice hulling, rice bran separation, rice sand roller milling, rice iron roller milling, rice color sorting, rice grading, and packaging weighing.

Make a Quick Inquiry Now !Rice Destoner: The de-stoner is the first machine in the production line, efficiently removing impurities, stones, and other foreign materials from the paddy to ensure smooth processing in subsequent steps.

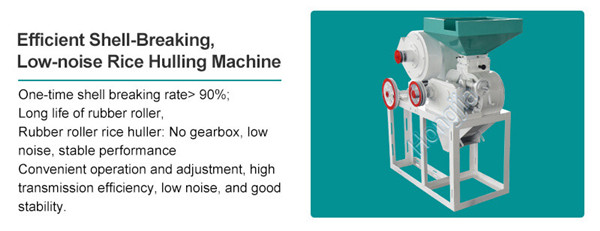

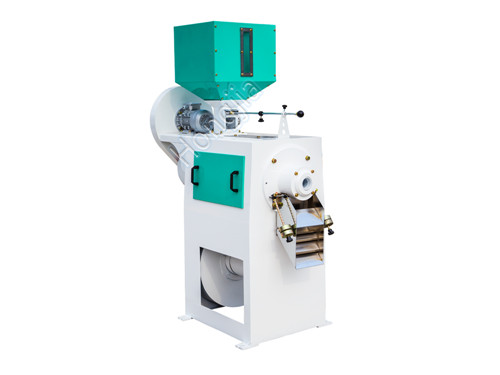

Rice Huller: The huller separates the rice husks from the grains using vibration and friction, preparing them for the milling process efficiently, and increasing the processing speed and efficiency of the paddy.

Rice Separator: The bran separator separates rice bran and hulls from the milled rice, ensuring the purity and quality of the final product while reducing rice loss.

Rice Mill Machine: The sand roller milling machine and iron roller milling machine are the core equipment in the production line, milling the pre-treated paddy into polished rice. These machines offer different milling methods and effects, allowing customers to choose the appropriate model as per their requirements.

Rice Color Sorter: The color sorter removes impurities, foreign materials, and defective grains from the rice using optical technology, ensuring the color, quality, and safety of the final product.

Rice Grading Machine: The rice grading machine sorts the polished rice by size, shape, and other characteristics, meeting various market demands and improving the product's market competitiveness.

Rice Packing Machine: The packaging weighing machine efficiently packages the processed rice in predetermined weights, ensuring the quality and packaging standards of the product.

The customer expressed great satisfaction with the rice milling machine set, praising its efficiency, quality, and performance. Their satisfaction was not only evident in the effectiveness of the equipment but also garnered recognition and praise from the local government, affirming the customer and our team's efforts.

This successful collaboration will help establish a favorable brand image and reputation in the Kenyan market, bringing more business opportunities and cooperation. We will continue to maintain close communication and cooperation with customers, continuously optimizing products and services to meet market demands and achieve mutual development.

The rice milling market plays a significant role in Kenya's domestic agricultural economy. Rice milling is the process of processing paddy into rice. Rice mills are typically located in rural areas or near rice paddies, responsible for processing paddy into rice and then selling it to wholesalers, retailers, or directly to consumers. Currently, the rice milling market in Kenya faces some challenges and opportunities:

Supply chain issues: Some rice mills may face challenges with supply chain interruptions due to transportation difficulties, and inadequate infrastructure, especially during seasonal harvest peaks, which may lead to insufficient processing capacity or delivery delays.

Technological upgrades: Some rice mills may need to upgrade equipment and technology to improve production efficiency, reduce costs, and enhance product quality. Technological upgrades may require investment and technical training, which could be a challenge for some small-scale rice mills.

Market demand: With the growth of Kenya's economy and accelerated urbanization, the demand for rice is increasing. Therefore, the rice milling market needs to adapt to changing consumer demands, including providing a greater variety of rice products and higher-quality services.

Government policies: Government policies and regulations also impact the development and operation of the rice milling industry. Governments may take measures to promote agricultural production, protect local producers, and enhance food safety standards.

Overall, Kenya's rice milling market has potential for growth and development but needs to address challenges in supply chains, technology, market demand, and policies to better serve the goals of the Kenyan people.

We warmly welcome rice milling machine demanders from around the world to collaborate with us! We are committed to providing you with the highest quality products and services to meet all your rice milling machine needs. Regardless of your location, we are ready to work together to create prosperity and development in the rice milling industry. With our experienced team and advanced technology, we can provide customized rice milling solutions, ensuring efficient, stable, and sustainable production processes for you.

Whether you are an individual user, corporate customer, or government agency, we will spare no effort to meet your needs, providing first-class product quality, excellent after-sales service, and competitive prices. We believe that through our efforts and collaboration, you will have a satisfying experience and achieve success.

Feel free to contact us and let's embark on a new chapter in the rice milling machine field, creating a brighter future together!

Comments

Post a Comment