What is Paddy Drying?

Different from the drying of other grains, rice is a heat-sensitive crop, excessive drying rate or improper selection of process parameters may easily cause bursting during the drying process. Considering various factors such as the characteristics of the rice itself and the quality of the rice to be achieved after drying, the following measures should be paid attention to when drying the rice:

(1) The drying process of drying + circulating is adopted.

(2) Select the appropriate drying retardation ratio. The drying retardation ratio refers to the ratio of the time for the grain to slow down and the time for the grain to be heated and dried during the drying process of the grain.

3) Use lower hot air temperature. To ensure the quality of rice after drying and reduce the burst rate, a lower hot air temperature must be used. If the hot air temperature of 38~40℃ is used, the increase of the burst rate is less than 2%. The burst rate during the drying process of rice is not only related to hot air. It is related to temperature, and it is also related to the content of thermal rheumatism and the initial moisture of rice.

4) Limit the drying rate of the rice. If the rice is dried too fast or cooled too fast, it is easy to cause the waste to burst. To ensure the drying quality of the rice, the drying speed should not be too high. greater than 1.5%. , It can be slightly adjusted according to the different drying processes. For example, if the drying process of drying + slow-suspension is used, the drying rate can be adjusted to between 1.5 and 2%.

Therefore, for the drying of rice with high moisture, the rice dryer adopts the batch cycle drying process, and the large and medium-sized rice dryer adopts the multi-stage drying + multi-stage circulating drying process, to reduce the cost of each drying process. The precipitation rate for a cycle batch or each drying section.

Low Temperature Circulating Batch Dryer

1. Introduction of low-temperature batch drying machine:

Small grain dryer circulating is a kind of small grain dryer developed by our company based on the continuous grain dryer. The circulating drying process of the machine solves the problem of a small grain dryer that can't dry high-moisture raw grains due to the short drying time.

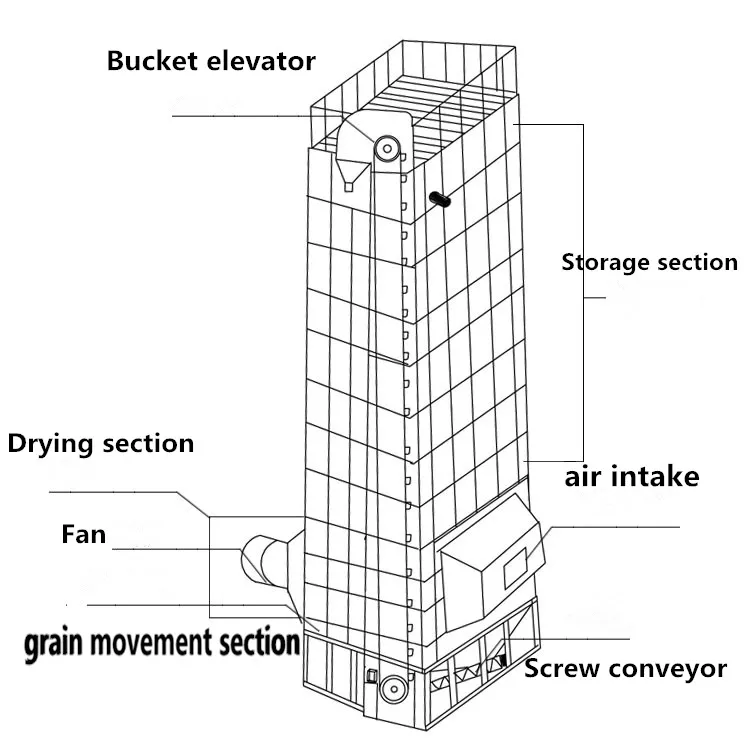

2. The structure of Lower temperature circulating batch dryer

CHJ series low-temperature circulating batch grain dryer is a steel structure. The machine consists of a grain storage section, drying section, transmission and lifting part, hot air furnace, full alarm system, automatic grain moisture detector, automatic electronic control device, and other components. It can be operated separately in a single machine and combined with double machines.

3. Working Principle

During the operation of the machine, as raw grains fail to reach the safe moisture level after being dried for the first time, they will then be circulated into the dryer for the second drying with the circulating delivery system. The moisture level of the grain will be tested in real-time at the exit of the dryer. Until the safe-moisture level of grain is reached, will the discharge valve be started to discharge the grain out of the dryer?

4. Grain Dryer Features

A. The circulating process extends the drying time without increasing the height of the dryer, ensuring the drying effect on high-moisture raw grains, saving cost, and reducing the floor space.

B. The multi-layer horn box structure inside the dryer makes the exchange between grain layers and hot air more thoroughly and evenly.

C. The patented six-impeller grain discharge mode makes the grain discharge on the whole section of the dryer more evenly and thoroughly.

D. The Dryer is set with multiple emergency grain discharge ports for easy maintenance and troubleshooting.

E. Coal or straw, wood, and other biomass fuels are taken as fuels for hot air furnaces. The combustion efficiency is high, significantly reducing the fuel cost.

F. Hand-fired hot air furnace and efficient steel tubular heat exchanger with the integrated structure of hot air furnace and heat exchange is equipped. The hot air furnace is built overall, high in strength, and durable.

G. An Online tester of grain moisture is equipped. The whole machine adopts a one-touch intelligent automatic control and touch-screen operation interface, intuitive in-display and easy to operate, and has a manual control mode and automatic hot-blast temperature adjustment function.

5. Grain Dryer Project Cases

Hongjia Grain Machinery Co., Ltd. was established in 2000. It is a professional manufacturer and exporter of rice mills, rice processing machines, rice processing plants, rice processing plants, paddy parboiling plants, etc. We can provide a unique overall layout design, customized rice mill products, and installation services for the rice mill production line according to the different needs of customers and site conditions. It combines technology, manufacturing, and sales in one.

If you are ready to Start a Rice Milling Business, please contact us for the Rice Milling Machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome, Contact Us!

Hongjia Grain Machinery Co., Ltd

Email: info@ricemillplants.com

Phone/Whatsapp: 0086 13196770111

Comments

Post a Comment